"Are those axles considered full float?"

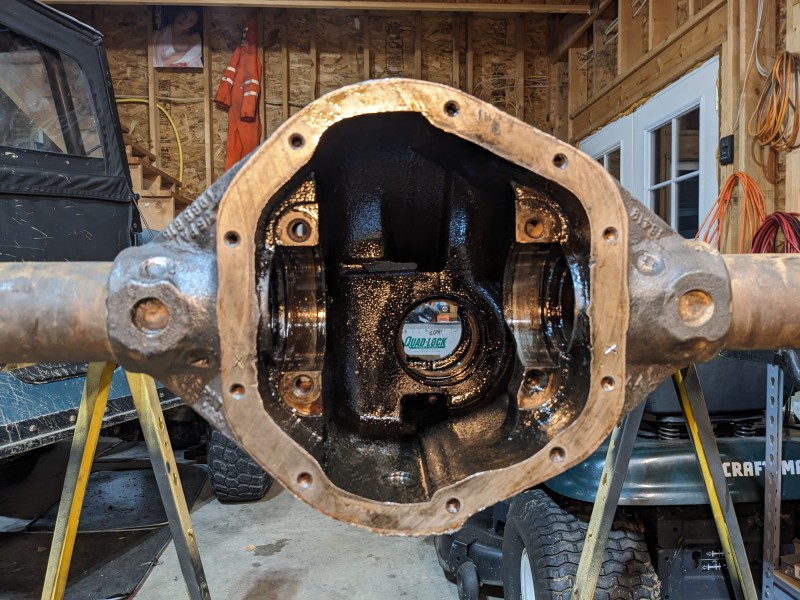

No....these are traditional 2-piece axles where the outer end of the axle shaft rides on a bearing that is set inside the outer end of the housing. The axle connects to the hub via a machined taper press on fit and a key/keyway.....the hub/axle keyway can be weak spot in these early D44s as can the shafts. A 'full-float' set-up would have the hub riding on a bearing that rides on a dummy 'spindle' shaft that is bolted to the end of the axle housing (just like a front axle minus the axle shaft u-joint and knuckle that allows for turning). The outer end of the axle shaft would be splined and connect to the hub via a female splined drive flange or locking hub (just like the front). The full float is not necessarily stronger in terms of the axle shaft - although it necessary to get aftermarket shafts which are often inherently stronger. And the splined hub/axle connection is no stronger than the tapered keyway, but the set-up allows for the ability for the vehicle to keep rolling on all 4 if an axle shaft breaks (and with removal of the broken shaft you can drive out in front wheel drive), as its the hub that is supported on the bearing and not the axle shaft. Blow up an axle shaft on the old 2 piece set-up, and its a PITA to get the jeep to even roll (so its hard to even tow it out)....

FWIW, This is some of the same challenges you see with the later AMC era model 20 differential found in the CJ5 and 7. The model 20 has a strong R&P, but weak axle shafts with a 2 piece design (and a weak axle tube as well). The old D44 2 piece is probably a bit stronger (albeit it wasn't often run behind the more powerful engines). The big change/improvement in the D44 (at least in the CJ vintage) started around the 1970 production year (so that includes my cj5), with a 1-piece design. The axle shaft has a flanged end that is also the wheel hub - thus '1-piece'. The axle shaft was also increased in size just a bit, axle housing increased in strength just a bit etc - proved a very strong design for most all builds of the vintage era. It is still not a 'full float' design, but the increase in strength and durability of the axle makes breakage must less likely - but yes, if the axle shaft breaks, its still a pain to tow it out on all fours. The design proved solid enough that many model 20 axles were later converted through aftermarket kits to 1-piece design (most notably moser axles).

Reply W/Quote

Reply W/Quote