So I bent the spindle on my 12" Delta drill press....this was a great used buy from our friend and member Pete Marshall (RIP), but I was kind of abusing it. So after realizing that there was no available replacement spindles other than to try and find a similar unit and salvage, I decided to go shopping for a new to me press (and might as well go bigger, eh?). I am not a huge fan of the quality new big box store or HF drill presses, and the slightly more quality stuff like JET is just out of my price range. Plus, most of what I was looking at in that new range was a 12-14" benchtop press - the 14 is realistically big enough - I just have to learn to treat it nicely. Big thing for drilling metal is getting slow enough rpm with enough hp to cut, and that is where a lot of the big box store stuff starts to lack.

The hardcore shop crowd like finding old made in the USA stuff which will last forever, but its hard to find, and often needs some love etc....There is also a window of time in the 80-90s when a lot of USA companies first went overseas with production, and they went to Taiwan, not China. Seems while that might have been a drop in quality from the old made in USA stuff, it was still good enough for the home hobbyist and I think way better than the new made in China stuff today. In the end, a lot of what drove my purchase was just what was available and trying to keep the budget small....So, for better and worse, with budget as convenient location a big determining factor, I went with this....

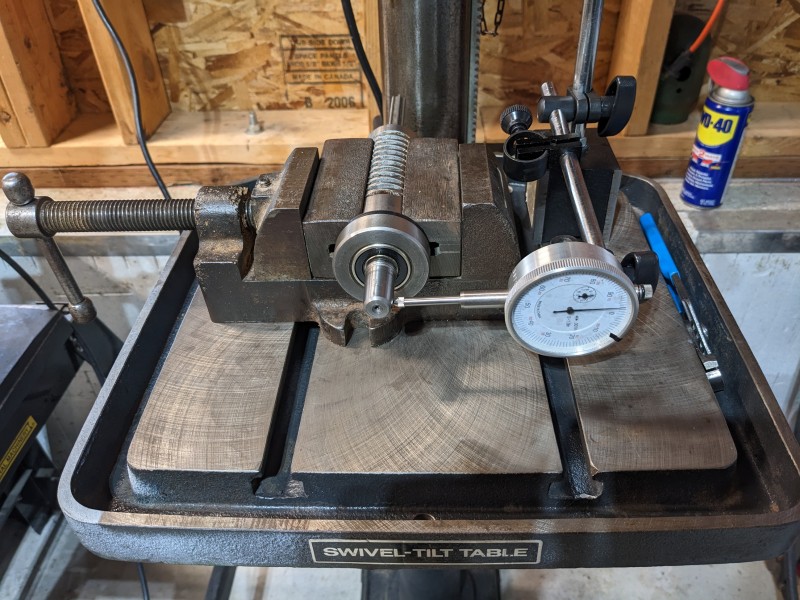

Its a 1985 Craftsman, made in Taiwan, 17", 16 speed floor model with a 3/4 hp motor.....its nothing special - not some old made in USA unit - but i think the original Taiwan stuff was serviceable for light home hobbyist like me....of course, after almost 40 years, how used and abused is it? I get that some find the old Taiwan stuff as junk - it might not have the longevity. This one seems to have sat mostly unused for quite a while....it runs quiet and true with little run-out (at least compared to what I've been using). After I get it set-up, I'll see if I can get a dial on it and measure the run-out. Also collected a couple of other items - vice and some 90 angle for round stock....

total damage was $150 and I didn't have to drive out of town to get it (most of the other used options i was looking at were a 2-3 hour drive away)....bodily damage moving a 200lbs object in and out of the truck might be different story....it certainly is pretty big - especially compared to the little 12" next to it, and one of my concerns with a floor model is dealing with its size and either mounting it or making some sort of stable base. The little benchtops drills are much easier to deal with - either mount to the benchtop or use a tool stand like I have under it. Guessing I will sink some concrete anchors and bolt it to the floor....simple large plywood base isn't as convenient in the space...I've read some discussion of maybe using the standard small base and a cable anchor of some sort to the ceiling rafter and/or wall studs behind it, or maybe I'll try to make a mobile base with casters.

Its getting a good cleaning and whatnot....don't think it was used a lot, especially in the last 15 years. Doesn't look like tons of parts are available for it, but even if it's not a keep it for a lifetime, it's okay at the price point. Basically it cost less than 'new' HF quality stuff today, and I am betting even at it's age, its a bit better machine...when you do hack shop work I do, I don't need a good machine anyway.

Reply W/Quote

Reply W/Quote